后疫情时代,鞋企如何突破自己的发展瓶颈? 订单暴增,如何降低成本,优化生产流程,实现智能制造? 鞋业厂家为了在严峻的市场竞争中脱颖而出,实现企业的可持续发展,必须坚持差异化竞争。如何做到差异化? 很多鞋企把目光放在了3D打印鞋,这一高新技术打造的新概念产品之上。

In the post-pandemic era, how can footwear enterprises break through their development bottlenecks? Facing a surge in orders, how can they reduce costs, optimize the production process, and achieve intelligent manufacturing? In order to stand out in the fierce market competition and achieve the sustainable development of enterprises, footwear manufacturers must adhere to differential competition. So, how to achieve differentiation? Many footwear enterprises have set their sights on 3D - printed shoes, a new - concept product created by high – tech.

经过多年的努力,目前联泰科技鞋模制造设备约占全国总制模3D打印设备的60%,覆盖全球多个产业集中地,国内福建、广东、山东、河南、河北,国外越南、印尼、巴西、土耳其等。“提供卓越的3D打印系统解决方案,运用3D打印技术革新传统制造及商业模式”这是联泰的企业使命,为了进一步推动产业发展以及与新老客户建立长期友好合作关系,联泰鞋业事业部在应用中对不断对技术进行升级以一系列优化方案为鞋类产业供应链中提供最具价值的解决方案,这也是联泰科技在制鞋产业应用中一直以来努力的方向。3D打印深入鞋业应用分为三个阶段,第一个阶段原型打印阶段,比如,打印木模、试穿软底;第二个阶段定制阶段, 批量打印真实鞋底;第三个阶段量化制造阶段,打印快速模具/金属模类/真实鞋底。同期,各种3D打印技术共同发展,SLA光固化技术、SLS选择性烧结技术、CLIP连续液体底投影技术、SLM选择激光金属成型等。光固化技术之所以在这一领域占据主导地位,是因为它提供了几种不同的技术选择,满足了多种关键鞋类应用的需求。

After years of efforts, currently, the footwear mold manufacturing equipment of UnionTech accounts for approximately 60% of the total 3D printing equipment for mold - making in China. Its business covers multiple industrial clusters globally, including Fujian, Guangdong, Shandong, Henan, and Hebei in China, as well as Vietnam, Indonesia, Brazil, Turkey, and other countries abroad. "Provide excellent 3D printing system solutions and use 3D printing technology to revolutionize traditional manufacturing and business models" is the corporate mission of UnionTech. To further promote industry development and establish long - term friendly cooperative relationships with new and old customers, the Footwear Business Division of UnionTech continuously upgrades its technology in applications. Through a series of optimization plans, it provides the most valuable solutions for the footwear industry supply chain, which is also the direction that UnionTech has always strived for in the application of the footwear industry. The in - depth application of 3D printing in the footwear industry can be divided into three stages: The first stage is the prototype printing stage, such as printing wooden molds and trying on soft soles; the second stage is the customization stage, where real - life soles are printed in batches; the third stage is the mass - manufacturing stage, where rapid molds, metal molds, and real - life soles can be printed. At the same time, various 3D printing technologies are developing together, such as Stereolithography (SLA) technology, Selective Laser Sintering (SLS) technology, Continuous Liquid Interface Production (CLIP) technology, and Selective Laser Melting (SLM) technology. The SLA technology dominates this field because it offers several different technical options to meet the requirements of multiple key footwear applications.

3D打印技术在鞋业领域的应用优势如下:

The application advantages of 3D printing technology in the footwear industry are as follows:

1.个性化定制

1.Personalized Customization

3D打印技术可以根据消费者的个体脚型数据,快速制造出符合其需求的定制鞋子。相比传统鞋制造,3D打印鞋能够为消费者提供更加舒适和合适的鞋子。

3D printing technology can quickly manufacture customized shoes that meet the needs of consumers based on their individual foot - shape data. Compared with traditional shoe manufacturing, 3D - printed shoes can provide consumers with more comfortable and suitable footwear.

2.轻量化设计

2.Lightweight Design

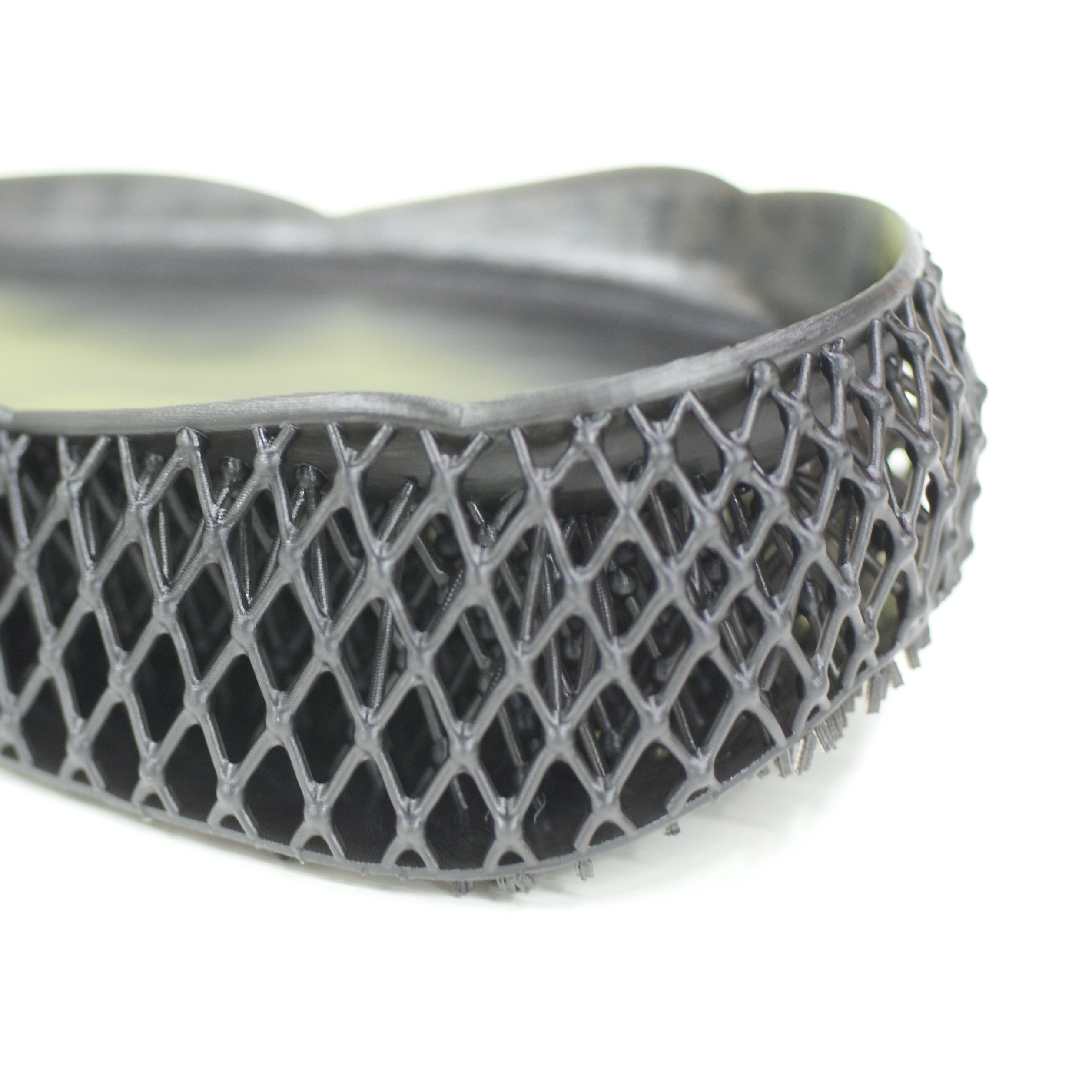

3D打印鞋可以根据不同部位的需求进行轻量化设计,减少鞋子的整体重量。这有利于减轻穿着者的负担,提高穿着舒适度,并在一定程度上提高运动性能。

3D - printed shoes can be designed with lightweight features according to the requirements of different parts, reducing the overall weight of the shoes. This helps to relieve the burden on the wearer, improve wearing comfort, and to a certain extent, enhance athletic performance.

3.设计自由度高

3.High Design Freedom

3D打印技术在制作鞋子时具有较高的设计自由度,可以制造出各种奇特的形状和结构。这种自由度使设计师能够创造出更具个性化和创意性的鞋款,满足市场多样化的需求。

3D printing technology has a high degree of design freedom when making shoes and can create various unique shapes and structures. This freedom enables designers to create more personalized and creative shoe styles to meet the diverse needs of the market.

4.节约资源

4.Resource - Saving

传统鞋制造过程中会产生大量的废料和浪费,而3D打印鞋则可以避免这些问题。它只需要根据需求制造所需的材料,减少了废料和资源浪费,对环境更加友好。

A large amount of waste is generated during the traditional shoe - making process, while 3D - printed shoes can avoid such problems. It only needs to manufacture the required materials according to demand, reducing waste and resource consumption, and is more environmentally friendly.

这项技术解决了制鞋领域的痛点:联泰科技独创数字化咬花技术

This technology solves the pain points in the footwear manufacturing field: UnionTech's original digital texturing technology.

联泰科技将数字化咬花技术引入设备,通过软件将花纹图位图片直接转换成皮纹贴于产品的3D数据上,将贴上去的咬花花纹连同整个产品一体打印出来。相对于传统化学腐蚀咬花,数字化咬花具有精细度高、成品表面质量好、绿色环保等特点,且生产制程更短,大大降低了生产成本。诸如此类与客户需求深度贴合的技术功能,让联泰科技的行业解决方案更具专业性。

UnionTech has introduced the digital texturing technology into its equipment. Through software, pattern images are directly converted into leather patterns and attached to the 3D data of products, and then the attached textured patterns and the entire product are printed integrally. Compared with traditional chemical etching texturing, digital texturing has the characteristics of high precision, good surface quality of the finished product, and environmental friendliness. Moreover, the production process is shorter, which greatly reduces production costs. Technical functions like this that closely meet customer needs make UnionTech's industry solutions more professional.

联泰科技自主研发的金属鞋模3D打印机,是其在鞋业模具界又一大技术攻关。立足于原有成熟的SLA 设备,在木模翻沙铸造应用中,联泰3D打印木模机已经十分普遍。金属鞋模3D打印工艺,将直接跳跃多个生产制程,提能增效,从而通过数字化智造升级整个产业。

The metal footwear mold 3D printer independently developed by UnionTech is another major technological breakthrough in the footwear mold industry. Based on the original mature SLA equipment, UnionTech's 3D - printed wooden mold machines are widely used in the application of wooden mold sand casting. The metal footwear mold 3D printing process can directly skip multiple production processes, improve energy efficiency, and thus upgrade the entire industry through digital intelligent manufacturing.

3D打印技术在IM EVA模具制造中的应用也非常灵活、快捷,它不仅可以有效降低制模所费成本,减少原料浪费,同时还可以在极短的时间内将设计创意具象为实际的产品,进而达到事半功倍的效果。

The application of 3D printing technology in IMEVA mold manufacturing is also very flexible and fast. It can not only effectively reduce mold - making costs and raw material waste but also transform design ideas into actual products in a very short time, achieving a multiplier effect.

3D打印技术在鞋业领域的运用并不拘泥于传统的鞋类设计,同时也助力于创意想象的无限发挥,为艺术设计提供更闪耀的舞台。

The application of 3D printing technology in the footwear industry is not limited to traditional shoe design. It also helps to fully explore creative imagination and provides a broader stage for artistic design.

随着增材制造技术的发展,佛像制作工艺正在由传统的手工雕刻转向3D打印数字化制作模式。在佛像制作领域已经有不少企业开始采用联泰科技3D打印机,并辅以联泰科技为雕塑行业研发的雕塑行业3D打印数字化解决方案,在佛像制作上获得了出人意料的效果,可谓是科技、宗教、艺术三者的有机结合。

With the development of additive manufacturing technology, the Buddha statue manufacturing process is changing from traditional hand - carving to 3D - printed digital production. In the Buddha statue manufacturing field, many enterprises have begun to use UnionTech 3D printers, combined with the 3D - printed digital solutions developed by UnionTech for the sculpture industry, achieving unexpected results in Buddha statue manufacturing, which is an organic integration of technology, religion, and art.

“感谢伙伴公司联泰科技,用科技的力量让设计细节通过3D打印技术完美呈现,精致、高...

Artist Lu Renjie: "Thanks to our partner UnionTech. With the powe...

3D打印技术,赋予雕刻艺术家二次升华的能力!随着增材制造技术便捷性与高效性的不断深入人心,西丰佛艺的...

Huang Zhiliang from Xifeng Buddha Art: "3D printing technology endows sculptors with the abilit...

启航叁维成立于2018年,公司主营高端品质的动漫手办及雕塑制作。同时公司还会承接一些拆件服务、3D打...

Hong Jingguo, General Manager of Huizhou Qihang 3D Technology: "Qihang 3D Technology was establ...

联泰3D打印机使用效果令人很满意,我们使用π200动漫专机这款机器,打印的“场景小品”和“恐龙”至今...

Qiao Zhihang, Founder of Foxfire Mold Creation Studio: "The use of UnionTech 3D printers is ver...

在线咨询

服务热线